Reibungswärmeerzeugermaschine

In the winter months the usable public realm in northern and middle European cities is reduced. Parks and squares that host informal city life in the summer, become deserted in the cold seasons. Shopping malls, bars or cafés provide alternatives — but only for paying customers. This observation and hence the task of designing a public and free space that is warm enough for longer stays when it’s cold outside provides the background for this project — ultimately demanding for the development of a new type of space that doesn’t exist yet.

The fundamental requirement for the design is the heat needed to temper the space and the physical generation of said heat. Therefore the built structure should only serve on one hand as a structural framework that contains the heat generator and on the other hand as an envelope that keeps the heat in one place. Opposed to other buildings where usually the climate concept is implemented after spatial and structural decisions are made, in this project the climate defines size, appearance and spatial quality of the architecture.

With the goal of a space free of commerce comes the necessity for low operating costs, which leads to the use of free renewable energy sources.

At the chosen project location of Oslo in Norway the central river Akerselva provides a steady flow of waterpower, which by means of a watermill can be transformed into free kinetic energy.

The most direct transformation from this available kinetic energy to the desired thermal energy is friction. Other methods would demand for elaborate technical equipment and would not help define spatial qualities as most heat generators are designed to be hidden away in service rooms.

Rather than using a closed technical black-box, the heat generator should be as self-explanatory and simple as possible, allowing for it to reveal the underlying physical principle and thereby become the central part of the architectural space and create its identity.

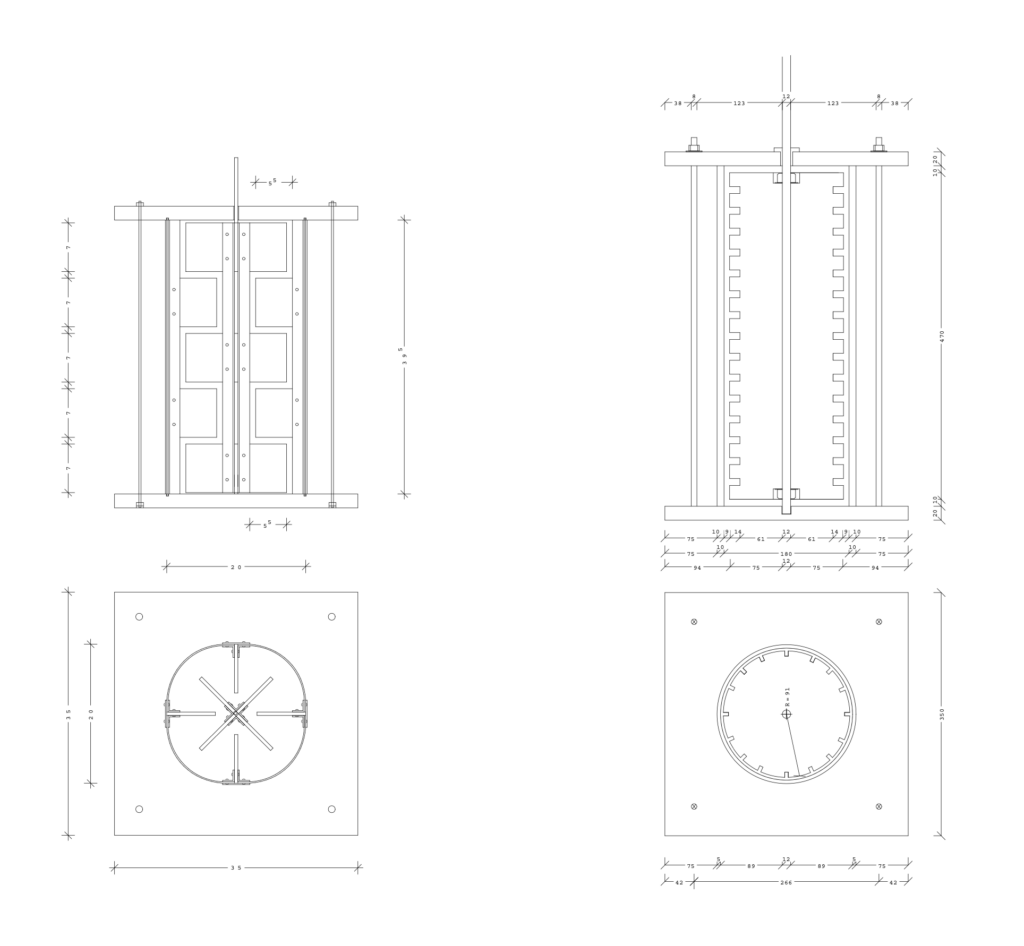

Relying on 19th century research of James Prescott Joule we developed a heat generating machine, where kinetic energy is used to generate friction in a fluid. By spinning a specifically developed ceramic rotor in a cylinder filled with oil, turbulences are generated that cause friction among the oil’s molecules, resulting in an increase in the temperature of the oil.

With the development and testing of different prototypes and measurement of the degree of energy conversion we were able to calculate the amount of thermal energy that was available from the river. With these values we then calculated the highest possible volume of the space with a defined interior temperature for the coldest months.

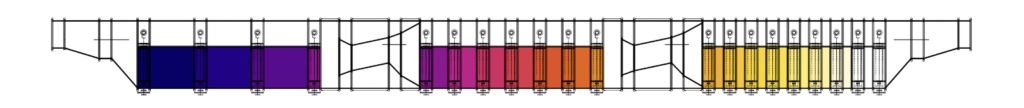

Finally, the proposed architecture is the result of combining the mechanical construction of the machine and the size of the calculated building volume and applying it to the chosen site vis-à-vis a historical water-powered flour mill in the area of Sagene in Oslo. Acting as an extension of a public path along the river the building is roughly 50m long and rising with the given topography. The floor is part ramp and part stair subdivided in length into three successive rooms. The subdivision manifests the physical phenomenon of heat rising up, which is additionally strengthened by the asymmetrical distribution of thermal energy to the different rooms through the number of heat generating machines per room. Ranging from four machines in the lowest to nine in the highest room the result is a perceivable difference in temperature while passing from room to room.

The typological outcome is an indoor ramp and stair which invites people to promenade but also stay and rest, talk, have a picknick or read a book in pleasant temperatures while being in a public place in the winter — tempered by self-explanatory machines, that generate heat from friction and are powered by free renewable energy.

Prototypes

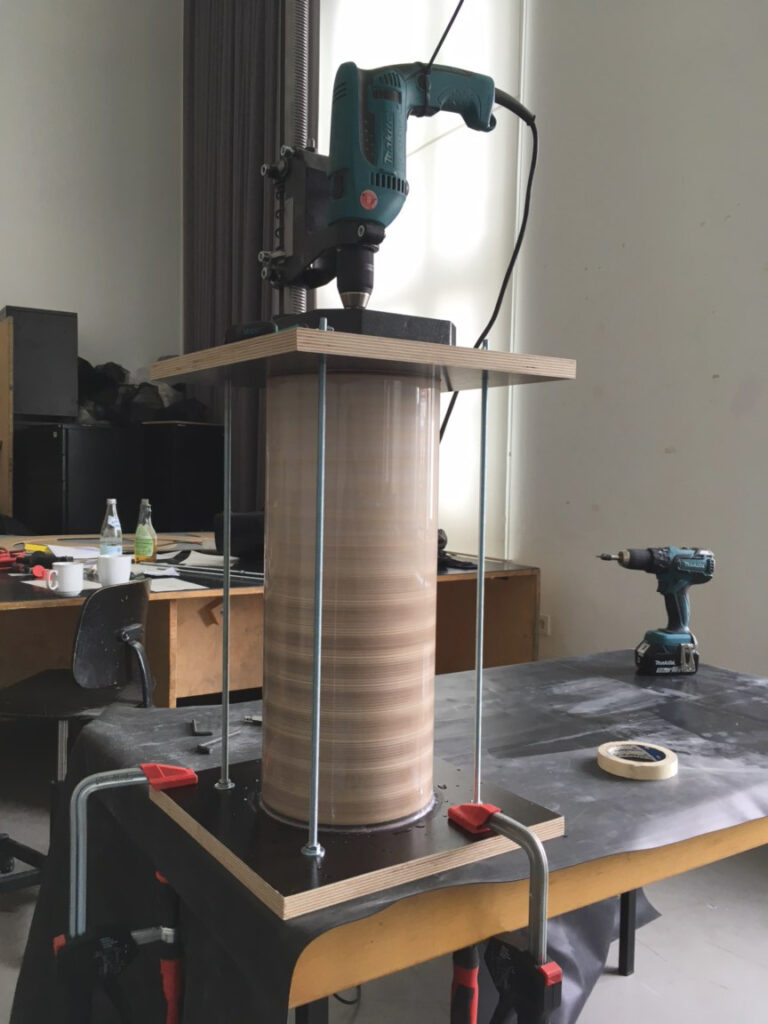

To test our concept and to quantify the amount of heat that can be generated with the friction heater we built two prototypes and put them through a series of longer and shorter tests.

The first prototype is a paddle rotor made from aluminium combined with a cylindrical vessel with fixed aluminium paddles. Once in rotation the moving paddles and the fixed paddles cause significant turbulance within the fluid.

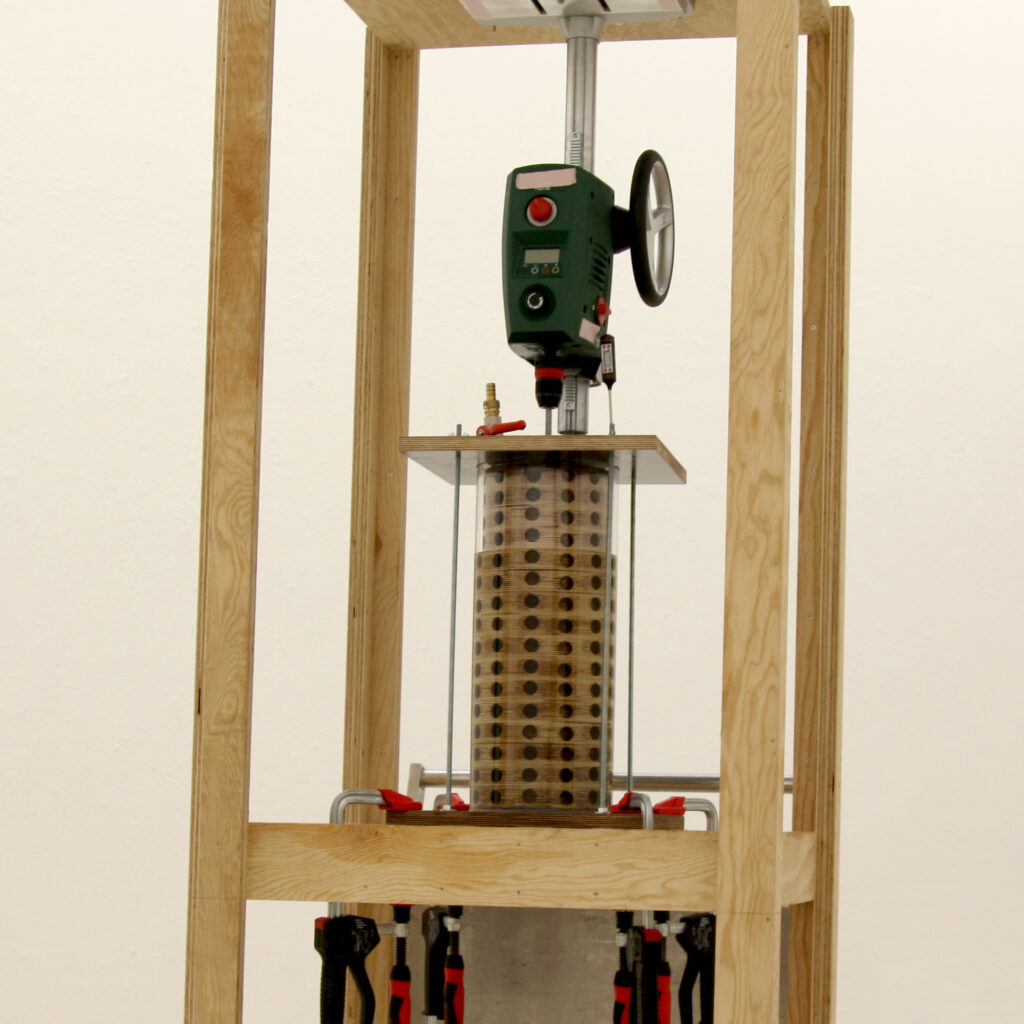

The second prototype is a wooden cylinder with 2cm deep holes all over the surface. This prototype can be rotated with higher speed than the first prototype and thus is able to create cavitation, which is the formation of vapour cavities in the fluid due to sudden changes in pressure caused by the holes in the cylinders surface.

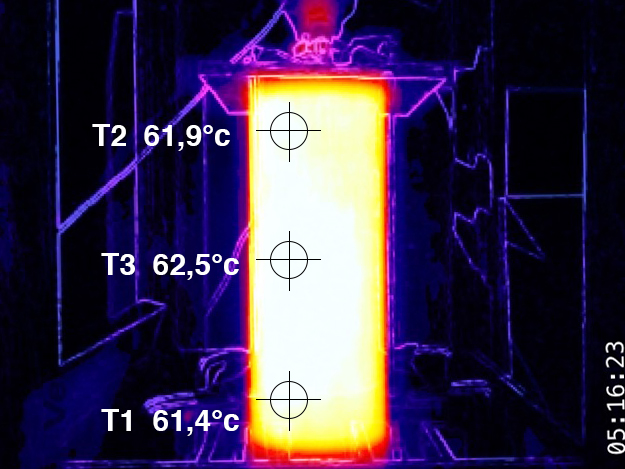

We ran both prototypes with a modified drill machine which we connected to a wattmeter to measure the induced power. The testing liquids were distilled water and canola oil.

Test Results

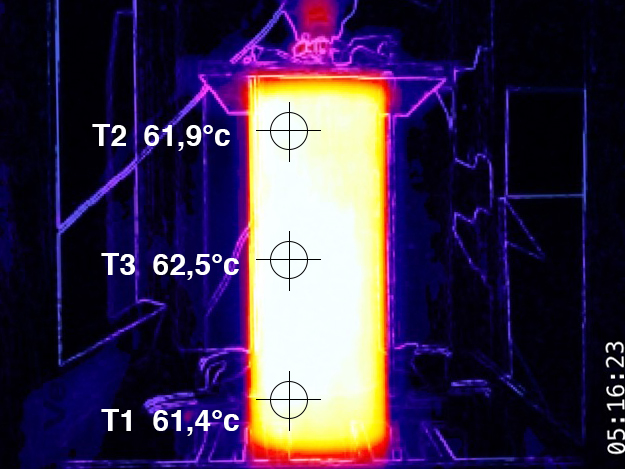

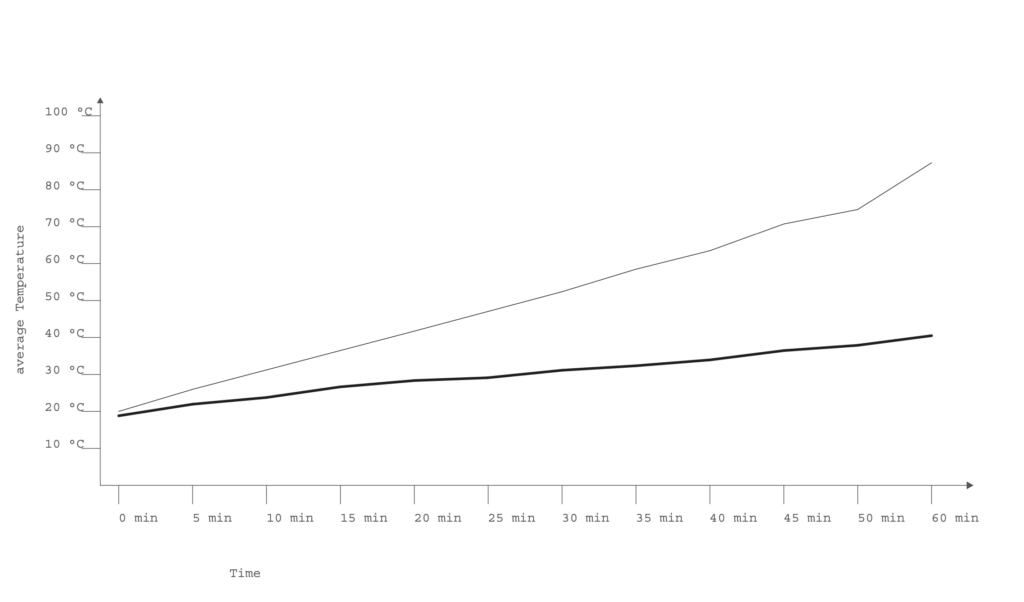

We ran both prototypes for the same amount of time and measured the increase in temperature.

The temperature of the 10 Liters of fluid in the first prototype increased about 21°C over the course of one hour with induced power of 380-500W and at constant rotation of 340rpm.

The second prototype allows for a lower volume of liquid (2.6 Liters) and higher rotation speed of 850rpm which leads to 67°C increase in temperature after 60 minutes.

The results in an efficiency factor of about 40% for Prototype 1 and about 20% for Prototype 2.

We studied the advantages of both prototypes, (which are higher volume and thus higher amount of turbulance in Prototype 1 and higher speed and thus the possibility of cavitation in Prototype 2) and concluded in the design for a second generation cylindrical rotor which is the underlying design for the architectural proposal.

Reibungswärmeerzeugermaschine is a research project in the fields of architecture, energy and mechanical construction by Soetje Beermann, Christoph Henschel and Johannes Ritz as part of their MA studies in architecture at the University of Fine Arts in Berlin.

It was supervised by Professor Christoph Gengnagel (Chair of Structural Design), Professor Christoph Nytsch-Geusen (Chair of Building Physics and Building Services Engineering) as well as Professor Gabriele Schultheiß (Chair of Garden Culture and Landscape Architecture) and Assistant Professor Lisa Tiedje (Chair of Experimental Design).

Name

Soetje Beermann, Christoph Henschel, Johannes Ritz

Year

2019

Type

Seminar Work